An engine typically refers to a machine or device that converts various forms of energy into mechanical energy to perform work. In the context of transportation, it usually refers to the power source of a vehicle, such as an internal combustion engine in cars or a jet engine in airplanes. Engines can also be found in various other applications, such as power generators, machinery. They come in different types, including combustion engines (like gasoline or diesel engines), electric motors, steam engines, and more. An engine produces horsepower and Nm of torque.

What is horsepower?

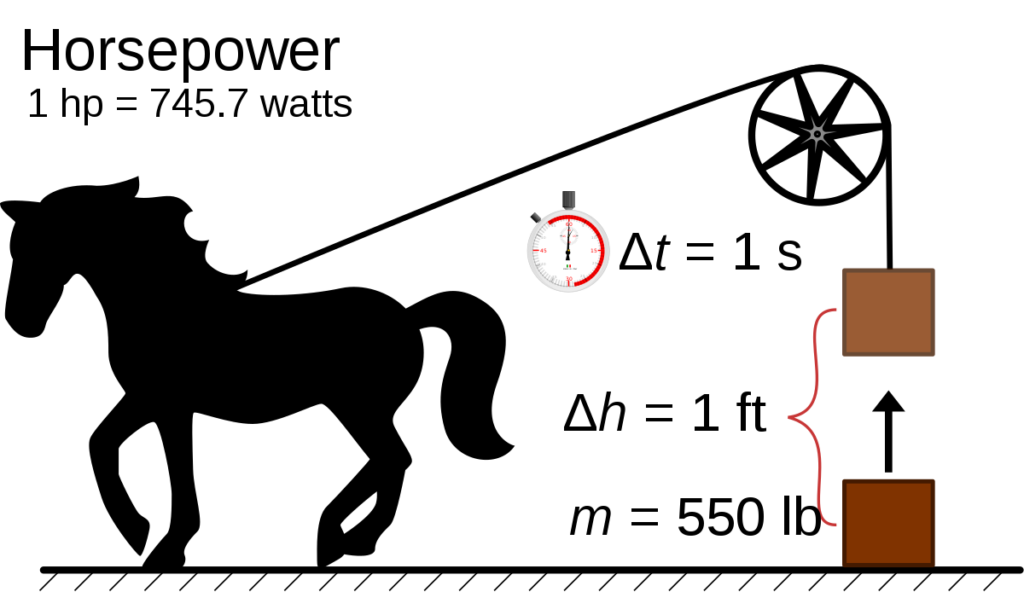

Horsepower (hp) is a unit of power, commonly used to quantify the rate at which work is done or energy is transferred. It was originally developed by James Watt, a Scottish engineer, to compare the power of steam engines to that of draft horses.

In modern usage, one horsepower is defined as approximately 746 watts. This means that one horsepower is equivalent to the power needed to lift 550 pounds by one foot in one second, or to move 33,000 pounds one foot in one minute.

Horsepower is commonly used to measure the power output of engines, particularly in the automotive industry, where it indicates the engine’s ability to perform work. The more horsepower an engine has, the more work it can potentially do in a given amount of time.

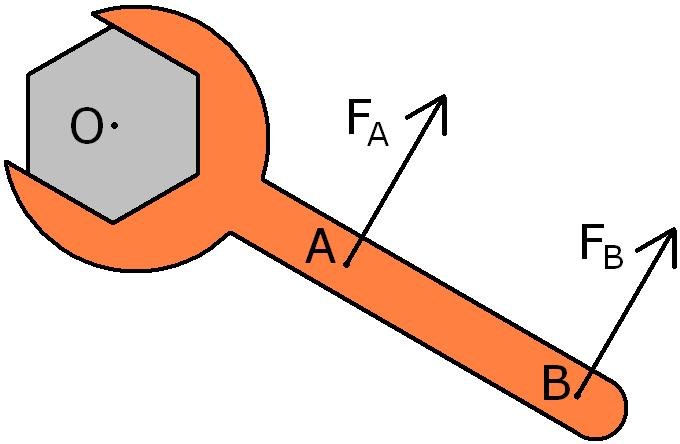

What is torque?

In cars, torque refers to the rotational force produced by the engine’s crankshaft. It’s a critical factor in determining the engine’s power and performance characteristics, especially in accelerating the vehicle and maintaining speed, particularly uphill or when carrying heavy loads.

Torque in cars is commonly measured in Newton-meters (Nm) or foot-pounds (lb-ft). It’s an essential consideration for various aspects of automotive engineering and design, including:

Acceleration: Higher torque helps in accelerating the vehicle more quickly, as it provides the necessary rotational force to turn the wheels.

Towing Capacity: Torque is crucial for towing heavy loads. More torque means the engine can provide the necessary power to move the load efficiently.

Hill Climbing: When driving uphill, torque becomes particularly important. It enables the vehicle to maintain speed and overcome gravitational resistance.

Engine Size and Type: Torque characteristics vary depending on the engine’s size, design, and fuel type. For example, diesel engines often produce more torque at lower engine speeds compared to gasoline engines.

Transmission: The transmission system in a car plays a role in torque delivery to the wheels. Different types of transmissions (e.g., manual, automatic, CVT) can affect how torque is applied and utilized.

Performance: Torque contributes significantly to a car’s overall performance, influencing factors such as acceleration, towing ability, and responsiveness.

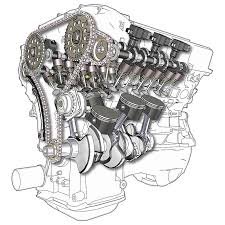

Mechanism of engine?

Mechanism of engine explanation:

- Intake Stroke: The engine cycle starts with the intake stroke. The intake valve opens, and the piston moves downward, creating a vacuum in the cylinder. This vacuum draws in a mixture of air and fuel into the combustion chamber.

- Compression Stroke: Once the intake stroke is complete, the intake valve closes, and the piston moves upward, compressing the air-fuel mixture. This compression increases the pressure and temperature inside the cylinder, preparing it for combustion.

- Combustion (Power) Stroke: When the piston reaches the top of its compression stroke, a spark plug ignites the compressed air-fuel mixture. The mixture combusts rapidly, generating a high-pressure explosion. This explosion forces the piston back down, generating mechanical energy.

- Exhaust Stroke: After the power stroke, the exhaust valve opens, and the piston moves back up, pushing the burned gases out of the cylinder and into the exhaust system. This prepares the cylinder for the next intake stroke.

This series of four strokes – intake, compression, power, and exhaust – make up what’s known as the four-stroke cycle, which is the fundamental operating principle of most automotive internal combustion engines.

Additional components involved in the engine mechanism include:

- Crankshaft: Converts the linear motion of the pistons into rotational motion, which is then used to drive the wheels of the vehicle.

- Camshaft(s): Controls the opening and closing of the intake and exhaust valves according to the engine’s timing requirements.

- Engine Block: Houses the cylinders, pistons, and other critical components of the engine.

- Connecting Rods: Connects the pistons to the crankshaft, transmitting the force of the expanding gases to the crankshaft.

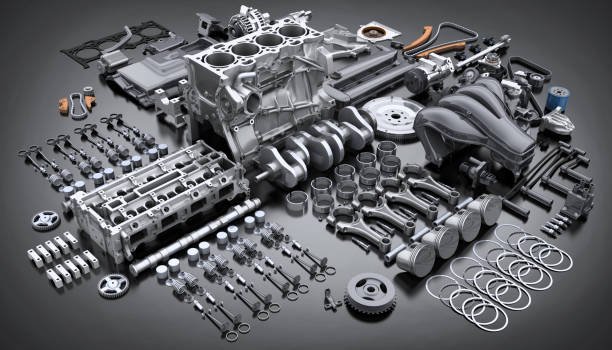

Engine parts:

Engine is a complex combination of many parts like: Cylinder Block: This is the main structure of the engine where the cylinders are housed. It’s typically made of cast iron or aluminum and contains passages for coolant and oil.

Cylinders: These are cylindrical bores machined into the cylinder block where the combustion process occurs. Pistons move up and down inside the cylinders.

Pistons: Pistons are cylindrical components that move up and down within the cylinders. They are connected to the crankshaft via connecting rods. Pistons help in compressing the air-fuel mixture, transferring force to the crankshaft, and expelling exhaust gases.

Crankshaft: The crankshaft is a rotating shaft connected to the pistons via connecting rods. It converts the linear motion of the pistons into rotational motion, which is then used to drive the wheels of the vehicle.

Connecting Rods: Connecting rods connect the pistons to the crankshaft. They transmit the force generated by the expanding gases in the combustion chamber to the crankshaft.

Camshaft(s): Camshafts control the opening and closing of the intake and exhaust valves. They are driven by the crankshaft via a timing belt or chain.

Valves: Valves are located in the cylinder head and control the flow of air (intake valve) and exhaust gases (exhaust valve) into and out of the combustion chamber.

Valve Train: The valve train includes components such as camshafts, lifters, pushrods (in pushrod engines), rocker arms, and valve springs. These components work together to actuate the valves according to the engine’s timing requirements.

Cylinder Head: The cylinder head is attached to the top of the cylinder block and contains the combustion chambers, valves, and ports. It seals the top of the cylinder, houses the valves, and provides passages for air and fuel flow.

Intake Manifold: The intake manifold distributes air (and sometimes fuel in fuel-injected engines) to the intake ports of the cylinder head.

Exhaust Manifold: The exhaust manifold collects exhaust gases from the cylinders and routes them to the exhaust system.

Timing Belt or Chain: This component synchronizes the rotation of the crankshaft and camshaft(s) to ensure that the valves open and close at the correct times during the engine’s operation.

These are the primary components of an internal combustion engine

Information:

More about us: About us

Contact us: enginepk0@gmail.com

Facebook page: https://web.facebook.com/profile.php?id=61559842490676

Nice work👍