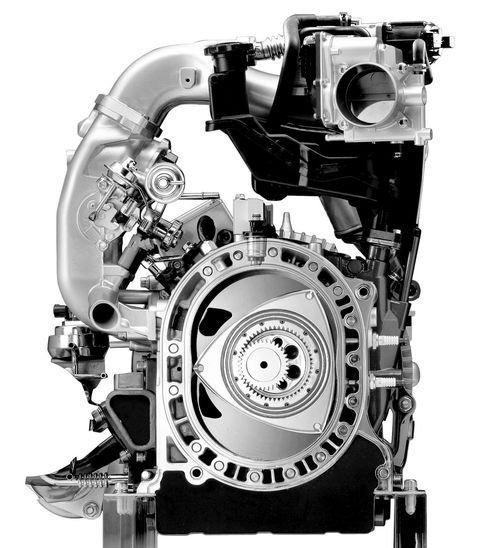

The rotary engine using a Japanese name of Wankel engine is an internal combustion engine quite distinct from the piston type of engine. Unlike the piston type which moves up and down in the cylinders, rotary engines employ a rotor which turns horizontally in a chamber around a central shaft.

Here’s how a rotary engine works:

Intake:

The rotary engine intake process starts with the rotor rotating from the center of the chamber as described below;. In the process, it forms a voluminous cylinder within the chamber that sucks in a blend of air and gasoline through other opening known as the port situated in the chamber area.

Compression:

Owing down the cylinder wall and, as the rotor continues to rotates it compresses the air-fuel mixture. This compression raises the pressure and temperature of the mixture with the aim of easily igniting the substance to produce heat.

Combustion:

The spark plug fires the fully compressed air-fuel mixture mentioned above. This lead to an explosion and causes the rotor to turn in the process generating power.

Exhaust:

Following combustion, the exhaust products of the gasoline-air mixture leave the cylinder through exhaust ports as the rotor continues to turn, thus ending the cycle.

Rotary engines offer some substantial benefits as compared to piston engines; reduced part count, efficient and less noisy, and better power-to-weight ratio. However, they also pose some drawbacks especially in terms of fuel consumption and emissions compared to traditional hydrogen engines.

Even though the design and mechanical properties of rotary engines are quite different from the piston engines, the piston engines are widely used than the rotary engines in many automobiles. Although, they are still in existence in some specific areas like in some sports car manufactures and aircraft manufacturers.

For any question feel free to Contact us

For more information visit our Facebook page https://web.facebook.com/profile.php?id=61560477510733&_rdc=5&_rdr